The «Botta Mountain Oasis»

The “Botta Mountain Oasis” is a project that deserves superlatives in many respects. A famous architect, a sensitive landscape, a challenging concept, plus constructive, technical and logistical tasks, some of which were uncharted territory for the contractors, but which of course had to be realised without compromise. Although the opening was not due until the 06/07 winter season, the most striking part of the project has already been completed.

Grand Hotel Tschuggen Arosa

The Grand Hotel Tschuggen in Arosa is an institution with an eventful history. Founded in 1883 as the "Sanatorium Berghilfe" for the treatment of lung patients, it became a grand hotel for winter sports enthusiasts with the transformation of Arosa into a winter sports resort. The entire property burnt down in 1966, was rebuilt in the style of the 1960s and reopened in 1970. In 1980, it came into the possession of the current owners, the Kipp family, who have been completely renovating the hotel's infrastructure since April 2004.

What is indispensable in today's hotel industry is being completely rebuilt: a wellness centre. From 2007, the Grand Hotel will extend its operations to cover the whole year.

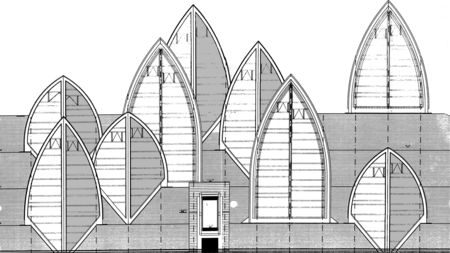

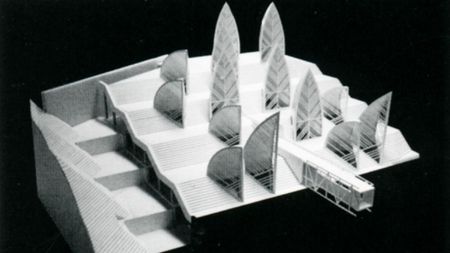

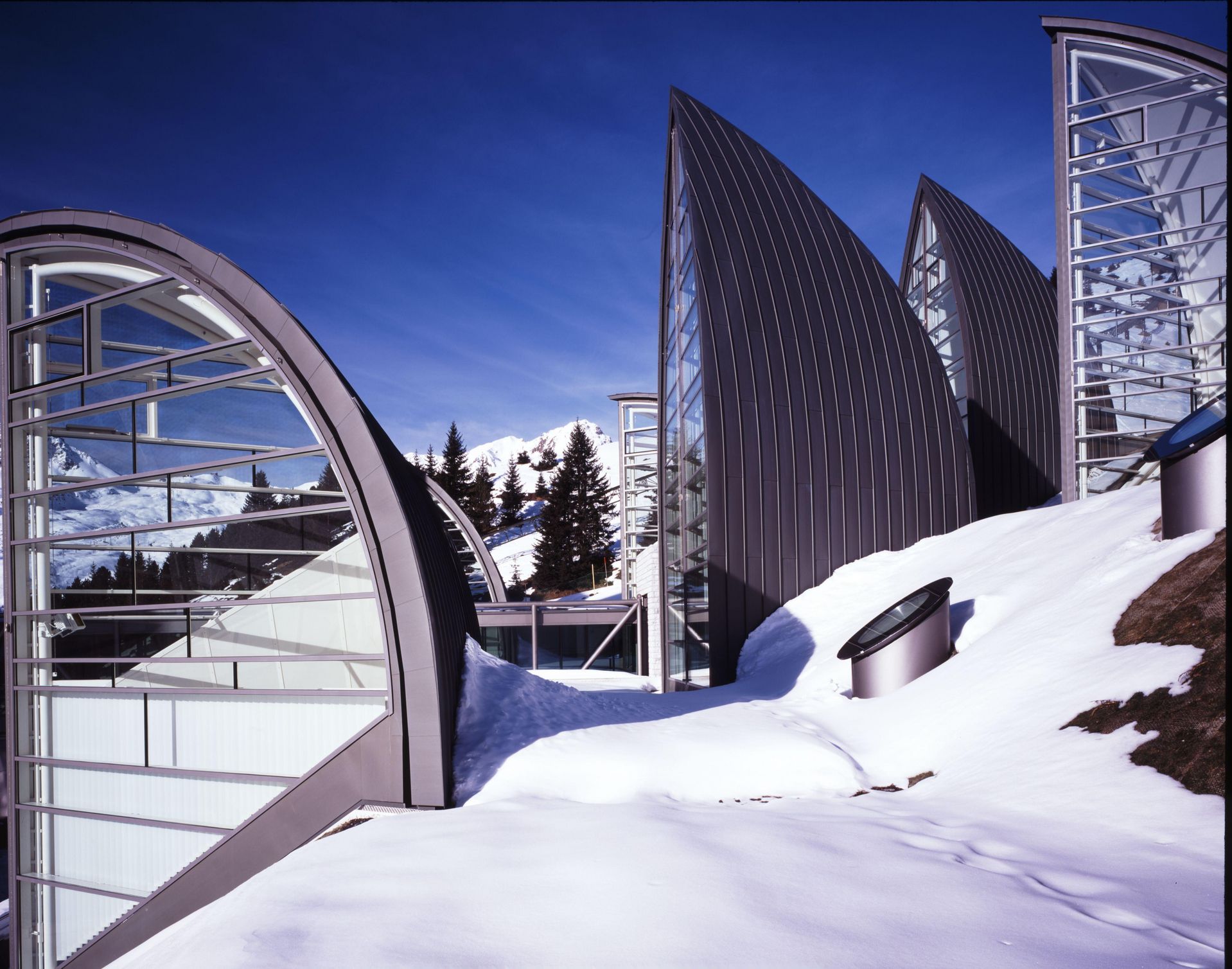

A grand hotel also needs a grand design, an architectural statement that scores points in the competition for prestige and guests among top hotels. The design by star architect Mario Botta hides the voluminous structure of the wellness centre in the adjacent mountainside. It was first demolished in order to construct the building conventionally. Finally, the slope is backfilled on top of the ceiling construction and planted with greenery. In this way, the wellness centre blends in almost invisibly – if it weren't for nine huge sails, that seem to be fully exposed to the wind. Glazed towards the site, covered on the back with pre-weathered, graphite-grey Rheinzink sheet metal and lined with light-coloured walls on the inside, they catch the daylight and guide it down through the triangular base into the interior of the wellness oasis.

The architect calls these structures "geometric-vegetal bodies". Inside, guests can look out through the light sails from open galleries, and at night the light sails shine out into the town.

Why RHEINZINK-prePATINA ECO ZINC?

Smaller CO2 footprint, 100% recyclable, extremely durable, practically maintenance-free -

making it the perfect future building material for sustainable construction.

When nothing is normal

1800 metres above sea level, the light sails have a lot to endure. The stimulating and healing bracing climate has a gruelling effect on the building fabric in the long term. In summer, temperatures can climb as high as 80°C in direct sunlight. And in winter, when it's freezing cold outside at minus 30 degrees, the warm and humid wellness climate of the baths and saunas prevails inside. Extreme climatic conditions – heat, cold, humidity,

dryness, rapid changes, one-sided sunlight, storms, rain, snow, heat and humidity in the wellness area, condensation and whatever else can be found in the building physics chamber of horrors – here they all work together, jointly or in opposition, in any case in permanent change and extreme effect. If you add up all the factors, it becomes clear how carefully all the measures for insulation, heating and ventilation have to be planned, dimensioned, processed and installed.

The long road from sketch to concrete detail

A cursory glance at the sketch reminds the mountain dweller of fir trees or leaves, while the flatlander is more likely to recognise a sailing regatta at the Kiel Week. The architectural model shows the concept, but after the design, the real work begins. Nine elements stand on equally sized triangular ground plans sloping down the valley, one part with the glazed top facing the village, the others with the roofed top facing the slope. With three different heights between nine and sixteen metres, there are four different types, each with its own shape.

Thinking and constructing in three dimensions

Geometric-vegetal (amorphous) bodies refuse to conform to the usual two-dimensional concept. This is why dimensions, shapes and radii are calculated in the 3D program right from the start. Step by step, the shapes of the five light sails are created from spatial sketches. They are shown in various views and rendered from different perspectives in order to harmonise the dimensions and proportions of the individual building types. This is followed by the detailed planning of the basic structures made of a load-bearing round tube frame welded at the junctions. A square tubular frame is placed on top of this. It reinforces the structure and is used to mount the façade, roof and installations. In the roof area, a timber construction is placed on this frame, to which the inner cladding, vapour barriers, insulation, cladding and finally the outer skin made of zinc sheeting are mounted.

Working group with local trade partners

The steel construction company Krapf AG is in charge of the construction of the light sails and has commissioned other specialists for the carpentry and sheet metal work. For the covering and sheet metal work, this is the consortium of the three tinsmiths Scherrer Metec AG (formerly Jakob Scherrer Söhne AG, Zurich), Renato Egli (St. Gallen) and Ludwig Waidacher (Arosa).

This consortium combines the expertise of Scherrer Metec AG, known for its demanding projects, with the local companies, as both the high altitude and the local conditions present particular challenges. It is always wise to involve regional companies in the realisation of such projects. They are familiar with the local conditions, can deal with the climate and politics, and of course strengthen the local craftsmen's capacities. For example, 12 tinsmiths were on site at the same time for assembly.

How do the light sails get up the mountain?

The metal construction company rents an industrial hall in St. Gallen and installs a huge metal cuboid there as an assembly template. This jig is used to fix the frame parts of each individual sail with millimetre precision so that they can then be joined together. A CNC-controlled machine bends the load-bearing tubes into the exact shape, the various radii of which were previously calculated by the 3D design. The state-of-the-art machine monitors the target and actual dimensions during bending and can correct the process. The result is precision with unusually low tolerances of ± 5mm.

Because the frame constructions, which are up to 13 metres high and weigh four tonnes, are too bulky to be transported to Arosa, they are dismantled again. The individual parts undergo various finishing processes (sanding, coating, painting) before being loaded onto lorries that transport them from St. Gallen to Fideris. A place is prepared there where the frames can be reassembled and picked up individually by a helicopter. Each flight up to Arosa takes 20 minutes. There, the frame is placed directly onto its prepared foundations by helicopter.

Another challenge: just-in-time logistics

At this height, the construction season is limited to a few summer months, and zinc would have to be heated before seaming in cold temperatures. And because all construction and weather risks are borne by the contractors in accordance with the required all-inclusive quotation, strict work and time management is required from the outset. At the same time as the frames are being installed, the individual elements for the timber and sheet metal structures are pre-produced. For the roofing, 1000 m2 of zinc sheet is processed, cut into 780 pieces and preformed. They are then packed according to parts lists for each of the nine elements. As soon as a frame is erected, the parts are also on site so that work can begin immediately on the extension and roofing. This just-in-time logistics is unusual for craft businesses. It requires not only a well-organised workshop, but also good coordination between the partners and with the construction work on site. This logistics exercise has to be repeated for each of the nine sails. The unusually favourable weather conditions in the summer of 2005 allow construction to progress so quickly that all nine elements can be assembled and completely removed before the onset of winter. The installation of the 1000 sqm. of sheet metal roofing was completed just-in-time within only seven weeks.

Client: Grand Hotel Tschuggen, Arosa

Architect: Mario Botta, Lugano

Overall project management: Mario Botta and Fanzun AG, Chur

Metal construction: Krapf AG Metallbau, Engelburg SG

Roofing and sheet metal work: Tinsmith Scherrer Metec AG, Zurich Arosa; Tinsmith Egli, St. Gallen Tinsmith Waidacher, Arosa

You are on our global website.

Would you like to stay on rheinzink.com or visit the local RHEINZINK America website?